AS/RS ( Automated Storage and Retrieval System) - Transforming Warehousing with Intelligent Automation

The AS/RS is an advanced warehousing solution designed to optimize storage efficiency, enhance operational accuracy, and reduce labor costs. By leveraging automation and smart technology, AS/RS integrates seamlessly into modern warehouse, enabling precise inventory management and streamlined workflows.

Automated Operations:

Uses robotic systems to handle storage and retrieval tasks, eliminating manual labor and minimizing errors.

Space Optimization:

Maximizes vertical storage space, allowing for high-density storage even in limited floor areas.

Real-Time Inventory Tracking:

Features advanced software for real-time inventory monitoring, ensuring accuracy and reducing stock discrepancies.

Customizable Configurations:

Designed to accommodate various pallet sizes, load weights, and warehouse layouts, with flexibility for future scalability.

Energy Efficiency:

Equipped with energy-saving technologies to optimize power consumption and reduce operational costs.

Increased Efficiency:

Automates repetitive tasks, significantly reducing processing time and improving throughput.

Enhanced Accuracy:

Precise inventory management minimizes picking errors and ensures correct stock placement and retrieval.

Cost Savings:

Reduces dependency on labor while optimizing space usage, lowering overall operational costs.

Safe and Reliable:

Minimizes workplace accidents by reducing manual handling and operating within a controlled environment.

CE certificated heavy duty warehouse picking equipment storage rack

AS/RS(automatic storage retrieval systems) refers to a variety of computer-controlled methods for automatically placing and retrieving load from specific storage locations. An AS/RS environment would encompass many of the following technologies: Horizontal Carousels, Vertical Carousels, Vertical Lift Modules (VLM) and traditional Crane-in-Aisle Storage & Retrieval systems that utilize storage retrieval (SR) crane.

Make full use of space for automated warehouse is an important part of storage, storage of goods by using multi-level warehouse system, height can reach 30 meters, according to the needs of different types of elevated can set more than 12 meters high, middle (5-12 meters), and low (5 meters below). Compared with the library can save nearly 70 per cent of the area.

Realizing mechanization, automation, thus improving the management level of warehouse for automated warehouse system by shelves, stacker, loading and unloading conveyer, automatic control system and management information system, and can be completed in accordance with the instructions of the goods for warehouse operation, and access to the automation management, make the goods storage materials handling more reasonable. Because of using computer storage shelves, and management, can easily realize fifo, Chen reservoir for the new principle to prevent natural aging metamorphism, goods, rust, etc

Please inform us the listed information for a quick quotation of pallet rack:

1) drawings of your warehouse or rack system if possible

2) Your pallet size: Height (with goods)*Depth*Length? Which side is for forklift entry?

3) How many start bays and add on bays you want.

4) Clear warehouse height or Max forklift lifting height

5) Loading capacity of each level

6) Aisle width needed for forklift operation, as common 3000mm

We can provide free and professional warehouse rack Auto CAD drawing design based on your these above info, to solve your warehouse storage solutions.

Or pls let us know your rack size(H*D*W), nons of level, loading each level, qty of starter rack + Add-on rack.

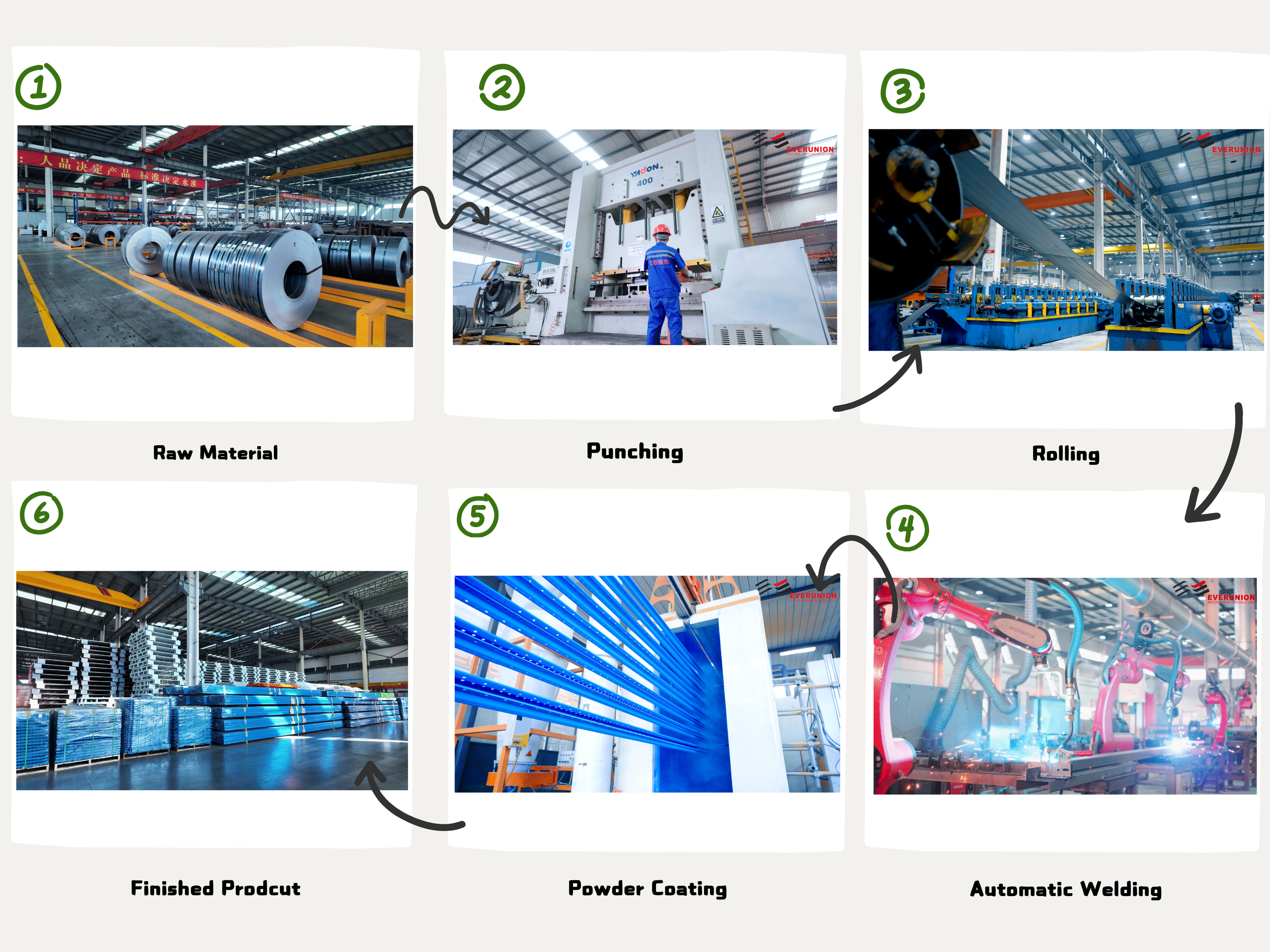

NANTONG FACTORY PHOTO

Nantong Everunion Intelligent Logistics Equipment Co., Ltd. is specializes in designing, manufacturing, intallaltion and debugging of racks .As a professional racking manufacturer , we can provide a wide range of racks, such as conventional pallet racks, Double deep racks, Drive-in racks, Narrow aisle racks, Push back racks, Radio shuttle racks, Gravity pallet racks, Cantilever racks ,Mezzanine, steel platform and long span shelving system etc..

Our factory is located in Nantong, Jiangsu province, it covers an area of more than 40,000 square meters, also we have established a team of professional specialists to solve logistics problem, and they are preparing to offer the technical consultation and storage design at any time. Everunion has CE and ISO certificate. Our high standards and strict requirements make our high quality products . For high quality , competitive price and good service ,our products have won a high phrase among domestic and foreign markets

Q1: Are you a manufacturer or trading company?

A: We are a professional racking manufacturer in Nantong, Jiangsu, we have sales office in shanghai. From shanghai to our factory, it will take about 2 hours by car.

Q2: what is your warranty time?

A: The high standards in the design and manufacturing ensure us to support the products with a 10 years warranty time for your normal use, it is the longest manufacturer's warranty!

Q3: What is delivery times?

A: We have 2 GEMA powder coating lines and 4 automatic welding machines, which can ensure us very short delivery time—less than 18 days.

Q4: What is your payment term?

A: 1) As general, 30% T/T down payment and 70% against BL copy.

2) 100% LC at sight

Q5: Are samples available?

A: Yes, we can send some sections of samples for your reference by express.

Q6: what’s the loading port?

A: Shanghai port is the closest port to us.

Q7: what’s the material and finishing of your racks?

A: As general, our material is Steel Q 235, Finishing: Powder coating.

Q8: How can I get your quick quotation on my pallet racking project?

A: As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotation, we need to know the following information

1) Required Pallet Racking Dimension: Height*Depth*Length?

2) Number of Levels?

3) Loading Capacity of each level?

4) Racking Quantity?

Q9: How many racks could be fit into a 20' container or a 40' container

A: We coud tell you if you provide us below information:

1) rack dimension

2) rack quantities

3) rack loading weight

Our Advantage

1) Our quick reply

For a quick quotation, just send email to us. We promise to reply with a price within 12 hours

2) Our short delivery time

For selective pallet racking orders, we will promise to produce within 15 days. As a manufactory we can essure the delivery time according to the formal contract.

3) Our special exporting packages.

We have plastic clips on the beams to protect the beams from surface damage in the transportation, We have got the whole uprights wrapped with transparent plastic film.

4) More than 20 years experienceon rack manufacturing and export