Customizable Mezzanine Rack System for Optimizaed Storage Space

Mezzanine Platform is a high customizable product, so with your requirements and warehouse layout we can design the perfect solution to meet your demands. Just give us your layout and requirement, we will return with a nice solution. The Mezzanine Rack System is an ideal solution for maximizaing vertical storage in warehouses, factories, and distribution centers. By utilizing the height of your facility, it effectively double or even triples the available storage area without requiring additional floor space or construction.

Key Features:

Industrial Heavy Duty Warehouse Rack Steel Mezzanine Floor Storage Racking Systems

1.fullest space utilization

2.Provides direct access to all cartons

3.Loading capacity: 300--1000kg/sqm

Advantages of warehouse storage steel mezzanine platform:

1) With composite racking structure, patented light-steel floor panel structure

2) Floor panel with large load capacity, low cost, quick construction

3) Can be designed into one layer or multi-layers according to actual situation

4) Ensures fullest space utilization

5) Provides direct access to all cartons

6) Surface: Powder coated and color optional

7) General ways of transportation from 2nd floor to 3rd floor: Manual, elevating table, hoisting machine, conveying belt, forklift truck

8) Can be designed according to clients' requirements.

9) Loading capacity: 300--1000kg/sqm

Other useful information:

Accessories: we provide necessary component, such as horizontal , diagonal beam and screw.

Packing: bubble pack, or according to customer's requirements

Payment:T/T, L/C at sight, western union

Warranty: 3 years guarantee from the delivery date

MOQ: 1 Sets

Production capacity: 2000 tons/month

Port of Loading: shanghai Port, China

Required information for quick quotation:

1) The AutoCAD drawing or draft drawing of the warehouse and mezzanine.

2) The size of the warehouse?

3) How many layers?

4) The size of shelving?

5) The loading capacity of each layer?

6) The loading capacity of each square meter of the floor?

7) The RAL color?

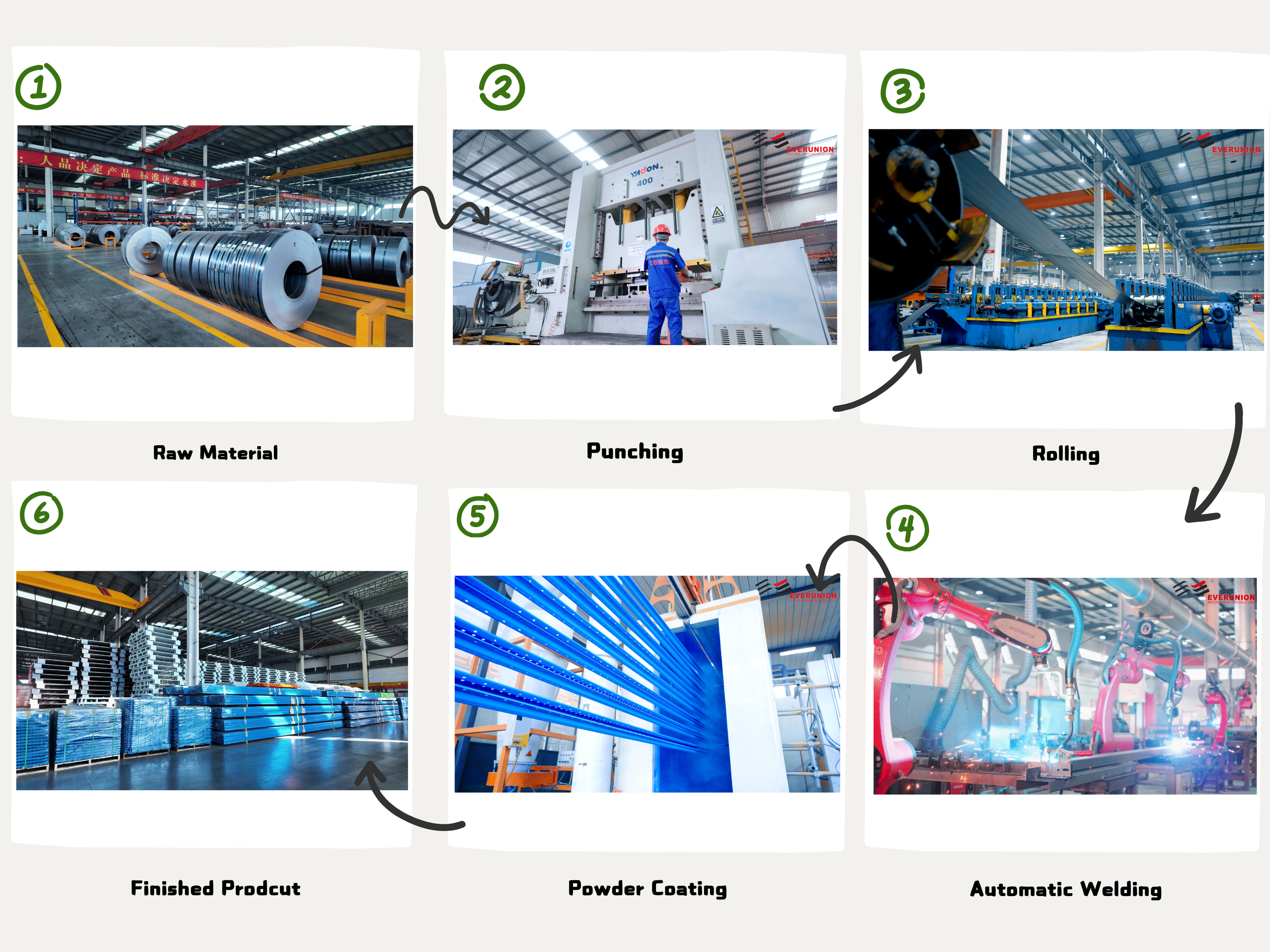

NANTONG FACTORY PHOTO

Nantong Everunion Logistics Equipment Co., Ltd. is specializes in designing, manufacturing, intallaltion and debugging of racks .As a professional racking manufacturer , we can provide a wide range of racks, such as conventional pallet racks, Double deep racks, Drive-in racks, Narrow aisle racks, Push back racks, Radio shuttle racks, Gravity pallet racks, Cantilever racks ,Mezzanine, steel platform and long span shelving system etc..

Our factory is located in Nantong, Jiangsu province, it covers an area of more than 40,000 square meters, also we have established a team of professional specialists to solve logistics problem, and they are preparing to offer the technical consultation and storage design at any time. Everunion has CE and ISO certificate. Our high standards and strict requirements make our high quality products . For high quality , competitive price and good service ,our products have won a high phrase among domestic and foreign markets .

We mainly export our racks to Mid-East, South America, Center America, Oceania, Africa, Europe and some Asian countries, such as Canada, Australia, Germany, Italy, Belgium, Greece, Czech Republic, Philippines, Indonesia, Jordan, Sri Lanka, Korea, Japan, Mexico, Guatemala, Chile, Brazil, Norway, Singapore and so on

We will always solve all the problems related to logistics for customers with our best products and best services. If you are interested in our products, please feel free to contact us for more information.

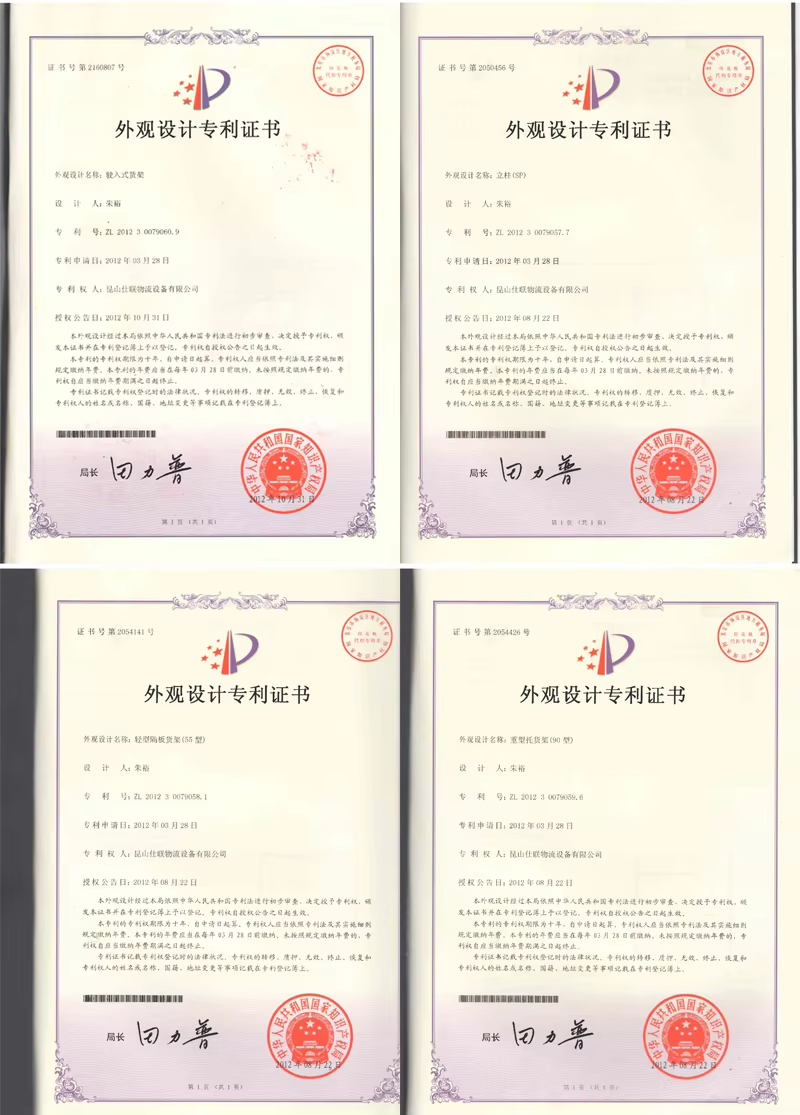

PATENT for RACK DESIGN

CE and ISO CERTIFICATE

TEST REPORT

Q1: Are you a manufacturer or trading company ?

A: We are a professional racking manufacturer in Jiangsu , Jiangsu , we have sales office in shanghai .From shanghai to our factory , it will take about 2 hours by car .

Q2: what is your warranty time ?

A: The high standards in the design and manufacturing ensure us to support the products with a 10 years warranty time for your normal use, it is the longest manufacturer's warranty !

Q3:What is delivery times?

A: We have 2 GEMA powder coating lines and 4 automatic welding machines,which can ensure us very short delivery time—less than 18 days .

Q4:What is your payment term ?

A: 1) As general, 30% T/T down payment and 70% against BL copy.

2) 100% LC at sight

Q5:Are samples available?

A: Yes, we can send some sections of samples for your reference by express.

Q6: what’s the loading port?

A: Shanghai port is the closest port to us .

Q7: what’s the material and finishing of your racks?

A: As general , our material is Steel Q 235 , Finishing: Powder coating .

Q8: How can I get your quick quotation on my pallet racking project?

A: As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotation, we need to know the following information

1) Required Pallet Racking Dimension: Height*Depth*Length?

2) Number of Levels?

3) Loading Capacity of each level?

4) Racking Quantity?

Q9: How many racks could be fit into a 20' container or a 40' container

A: We coud tell you if you provide us below information:

1) rack dimension

2) rack quantities

3) rack loading weight

Our Advantage

1) Our quick reply

For a quick quotation, just send email to us. We promise to reply with a price within 12 hours

2) Our short delivery time

For selective pallet racking orders, we will promise to produce within 15 days. As a manufactory we can essure the delivery time according to the formal contract.

3) Our special exporting packages.

We have plastic clips on the beams to protect the beams from surface damage in the transportation, We have got the whole uprights wrapped with transparent plastic film.

4) More than 20 years experience on rack manufacturing and export